04 Feb Telluride Science: “The Decarbonization of Cement,” an Innovation Workshop!

Telluride Science’s Telluride Innovation initiatives are all about expanding the frontiers of science and technology by exploring new ideas and building collaborations. Today these workshops are dedicated to scientists only and not open to the community at large. However, Telluride Science plans to expand its public programming once its new home is built out. For more on plans for the historic Depot, go here.

Go here to learn more about Telluride Science.

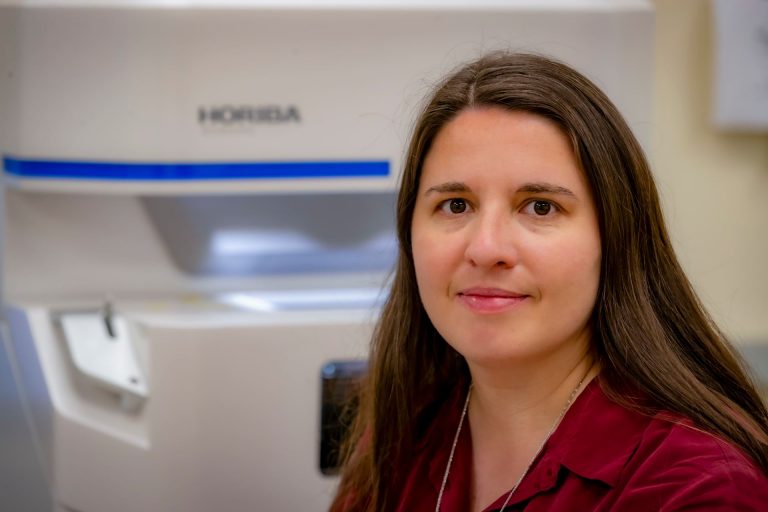

Dr. Iryna Zenyuk

According to The Economist:

“The Roman perfected concrete, and their legacy still stands in the form of the magnificent roof of the Pantheon, the world’s largest unreinforced concrete dome. Since it was completed in around 125AD by the Emperor Hadrian, an awful lot more concrete has been poured—some 30 billion tons every year, at the moment, to put up buildings, roads, bridges, dams and other structures. The grey stuff has become the most widely used construction material on the planet, and demand is growing.

“This is bad news for global warming…”

In a chess match played today between climate change and cement, cement would be heavily favored to win. In fact, if the cement industry were a country, it would be the third largest CO2 emitter in the world after China and America.

Just ask Iryna Zenyuk, Associate Professsor, Chemical and Biomolecular Engineering at the University of California, Irvine, (UCI), one of two featured speakers at Telluride Science’s upcoming Telluride Innovation Workshop, February 7 – February 11, 2022, on “The Decarbonization of Cement.”

Why Dr. Zenyuk? Once upon a time and for about 10 years she was ranked a Top 10 woman chess player and represented America at many international events. However, at the age of 28, Zenyuk decided to retire from the chess world, shifting her attention to renewable energy and decarbonization:

“I chose the energy field because I knew we will need to transition to a net-zero energy sector at some point and the electrochemistry discipline offered that solution.”

Specifically, Zenyuk’s background is in mechanical engineering. She also has a courtesy appointment in Mechanical and Aerospace Engineering Department at UCI, as well as in the Materials Science Department.

“Within chemical and biomolecular engineering (CBE) I am more of a chemical engineer and do not do research in bio-molecular,” explains Zenyuk. “However, I believe current global challenges require interdisciplinary solutions and we need all kinds of engineers and scientists to address the global warming challenge. The chemical engineering discipline historically worked closely with the fossil-fuel industry because chemical manufacturing and related sectors are heavy emitters of greenhouse gases. Therefore, we are very well-positioned to address the challenges the cement industry faces in meeting the difficult goal of net-zero emissions by 2050. That industry has low profit margins, so solutions need to be both clean – and cost-competitive.”

To date there are few practical alternatives to concrete but, as Dr. Zenyuk stated, technologies are being developed to make concrete greener. Green enough for the building material to go from adding CO2 to our atmosphere to subtracting it.

That is where Telluride Science weighs in:

“…The purpose of the Telluride Innovation Workshop…is to bring academic, industrial and national laboratory leaders together to brainstorm pathways to decarbonize the cement industry. The goal is to identify high-risk/high-reward technologies that have promise to reduce carbon intensity and increase energy efficiency in the cement-making process. Portland cement is the most widely used man-made material. But it is also responsible for 5% of the global energy consumption and 8% of the anthropogenic CO2 emissions…

“This workshop will address methods that utilize novel electrochemical processes to produce cement precursors, electrified methods to generate heat for cement production or alternative CO2 storage methods…”

The goal? To build a bridge, as Zenyuk suggests, between the cement industry and the electrochemical/electrolysis fields because electrochemistry is poised to play a big role in cement manufacturing over the next decades.

Dr. Zenyuk explains further:

“Cement has two major sources of CO2 emissions. The precursor for cement calcium carbonate has stored CO2 in it and, upon heating, it releases CO2. This is the first source of CO2 and it can be captured. The second source of CO2 is burning fossil fuels to achieve the high temperatures needed to transform calcium carbonate into cement clinker. Cement manufacturing happens at these high temperatures, so we need to either find a cleaner source of heat or transform the process completely, using low temperature and a pressure novel process. And this is where I believe the electrochemistry field can meet the cement manufacturing field to generate solutions that produce zero emissions, but are also scalable.

“My co-organizer Prof. Mo Li and I have a National Science Foundation research award on the development of a novel electrochemical process that relies on electrolyzers to produce calcium hydroxide from calcium carbonate. The process promises to reduce CO2 emissions by 25-75%. It is a low-temperature initiative which has the potential for scaling up. We are working on increasing its efficiency and reducing its cost.”

Dr. Iryna Zenyuk has been involved with Telluride Science for about four years.

“I think Telluride Science is a unique platform that encourages free discussions and sharing of scientific ideas. Its location is picturesque and its format allows participants significant amount of social time, which is also very conducive to creating new ideas and building collaborations.”

Collaborations which cement game-changing ideas that help save our planet.

Sorry, the comment form is closed at this time.